Al Jazeera Panel was set up in OMAN to meet the demand for quality insulated panels and has established itself as the regional leader in insulated roof, wall and cold store panel systems. Al Jazeera Panel has achieved consistent high quality in products and services as evidenced by landmark industrial projects in the region. Al Jazeera Panel directly contribute to improved building performance criteria including high standards in energy efficiency, fire resistance, air infiltration and environmental impact. Al Jazeera Panel provides customized insulated panel solutions to meet customers' objectives. Our sales executives together with our engineering personnel are available to provide solutions for your project requirements.

Our work is to provide the building market with technological innovation applied to the insulating panel and guarantee an efficient logistics and an excellent service in the most sustainable way from an environmental, social and economic point of view. We are not only suppliers of building materials, but a reliable partner always able to offer state-of-the-art solutions and grow with our clients. To reach this goal, the commitment and the passion of our staff and of our collaborators are paramount, just like the dialog with our clients, with whom we try to establish solid and lasting relations.

Al Jazeera Panel cares about your projects and helps you to realize them, starting from the concept to end with the final project. We promote a sustainable building industry, offering solutions for the renewal of the buildings, the reduction of consumption and of the waste of energy and resources. We contribute to the quality of the constructions through the use of reliable materials, in full conformity with the international standards. The Al Jazeera Panel products guarantee more efficiency, more innovation and more safety: the perfect thermal insulation and soundproofing of the buildings, their solidity, their air tightness and sound absorption contribute to protect them against fire by blocking it and limiting its extension. Our priority and that of our constantly up-to-date professionals and highly specialized technicians is to offer the right choice for our customers. Al Jazeera Panel knows the market and the materials very well and keeps itself constantly updated on the major trends and reference standards, marrying aesthetics and functionality.

Sandwich panels represent the achievements of construction technology. They are no less durable than traditional building materials, but much lighter and cheaper.

Sandwich panels are far cheaper comparing to other classic building materials. It also has a finished surface and does not need an additional maintenance.

Steel sheets can maintain the lastingness of the colour of the building, and reduce the solar radiation and keep the appropriate indoor temperature. Sandwich panels also have a good sound isolation feature.

Lightweight of sandwich panels affects the reduction of costs for equipping the basement; there is no need for heavy lifting equipment.

The working life of sandwich panels on average is about 25 years.

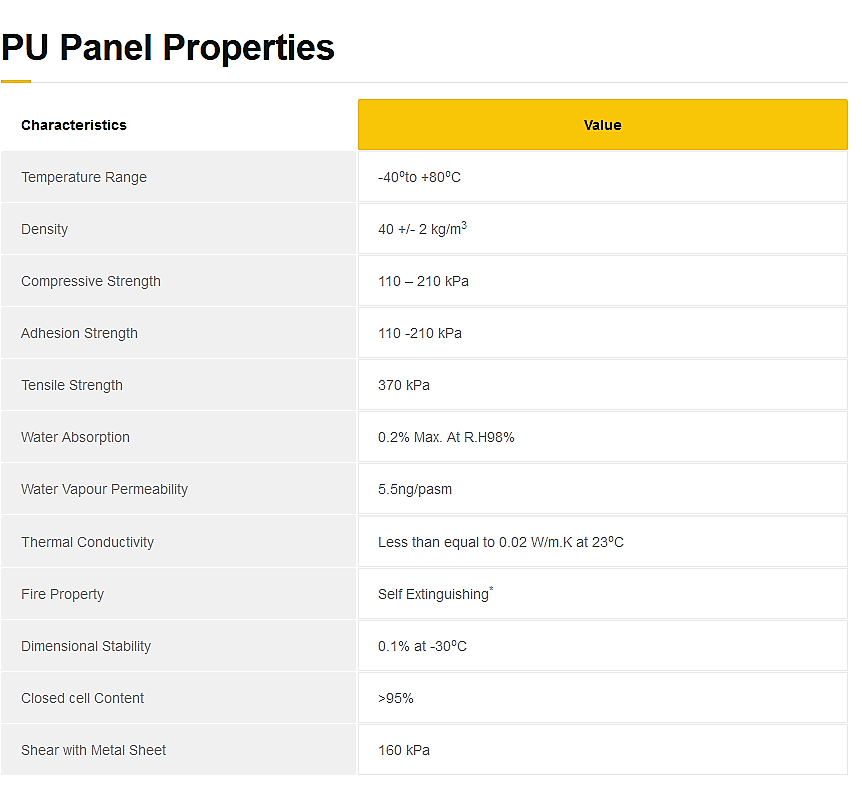

Polyurethane foam, which is used in the inner layer of sandwich panel, with its chemical components can reduce and prevent fire from spreading.

Sandwich Panel is the only material that allows disassembling the construction and erecting it somewhere else.

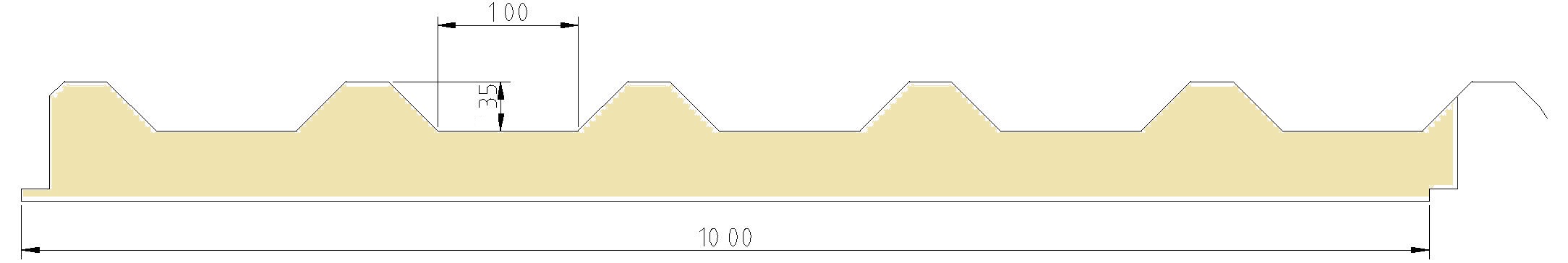

Built for beauty, durability and value, 5 Ribs Roof polyurethane sandwich panels are roof construction materials that perform in all seasons. Panels have the best thermal insulation with waterproofing and they stand out of long durability of exploitation and easy installation.

Use of these sandwich panels is a great solution for all types of buildings construction, including leisure, hospitals, industrial, retail, commercial, equipment storage, garages, boxes, cold and freeze stores houses and other applications.

Applications: for roofs

Upper side cover material: Prepainted galvanized steel

Lower side cover material: Prepainted galvanized steel or cardboard

Core material: polyurethane (PUR) core

Design: vertical ribbon, trapeze corrugated

Standard Colour: White grey (RAL 9002). Other colours are also available upon request

Width: 1000 mm

Length: Max. 12 m

Polyurethane Thickness: 50 mm – 100 mm

Thickness of Metal Surface: 0.3 mm - 0.6 mm

Polyurethane Density: 40 (±2) kg/m3

Flammability Class: B2 and B3

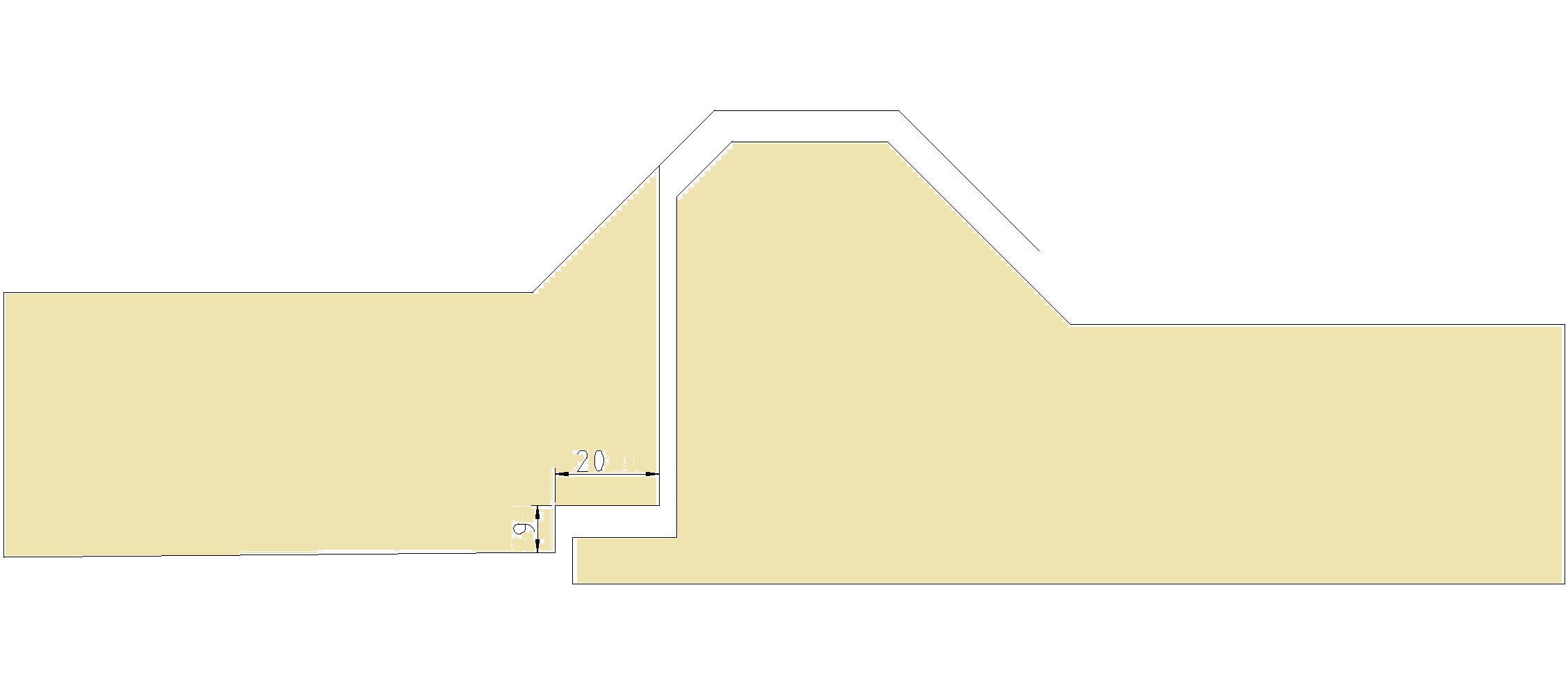

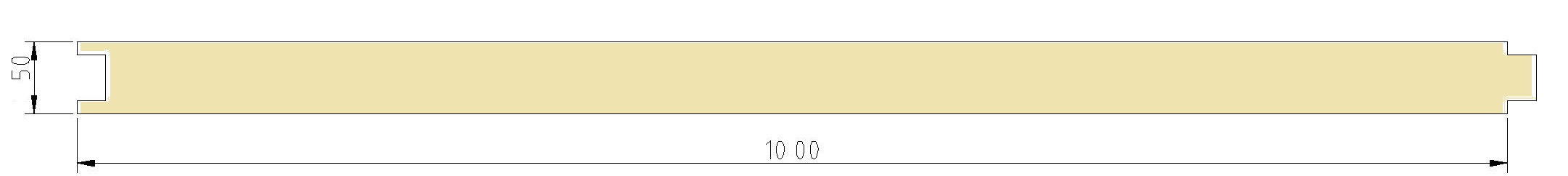

Strong heat-insulation characters, simplicity of construction, ability to be easily reassembled and durability, makes polyurethane Secret Screwed wall sandwich panels the best material to build different type of trade, commerce and public buildings such as shopping centres, warehouses, spotrs centres, storage, garages, boxes, sheds, cold and freeze stores etc.

Secret screwed wall sandwich panels can be assembled upon your taste and needs - vertically and horizontally. These panels contribute to a new kind of clear, simple and ordered architecture.

Applications: for walls

Metal Type: Prepainted galvanized steel

Core material: polyurethane (PUR)

Design: vertical ribbon

Standard Colour: White grey (RAL 9002). Other colours are also available upon request

Width: 1000 mm

Length: Max. 12 m

Polyurethane Thickness: 40 mm - 150 mm

Thickness of Metal Sheet: 0.35 mm - 0.60 mm

Polyurethane Density: 40 (±2) kg/m³

Flammability Class: B2 and B3

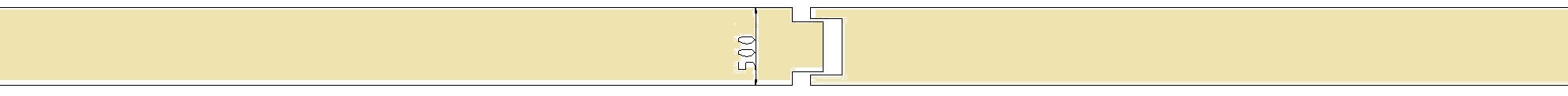

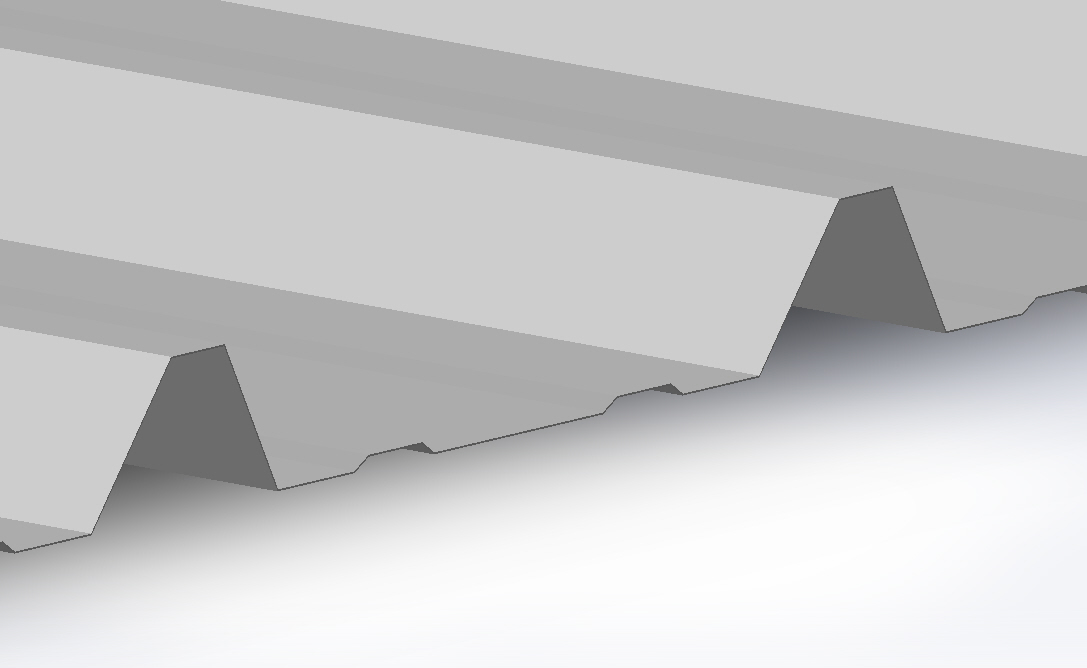

Corrugated sheet is a traditionally styled roofing sheet. Its low material cost and quick installation places its among the most economical products of all types steel sheets. The product can be easily used not only as roofing material but also as facade coverings and fences.

This material is recommended to use in case of no need of construction heat isolation.

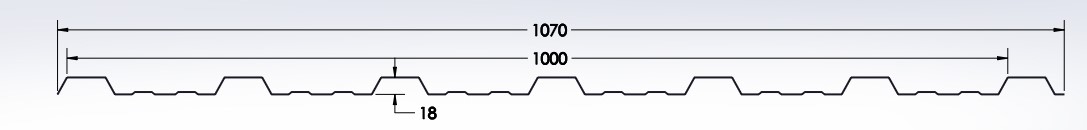

Profile 1

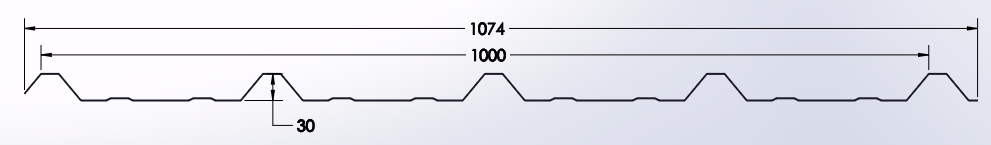

Profile 2

Application: Roof claddings

Metal Properties: Pre-painted Galvanized steel sheet

Sheet Thickness: Min. 0.25mm - Max. 0.5mm

Width: 1000 mm

Length: Min. 1000 mm - Max. 15,000 mm

Standard Colour: White grey (RAL 9002). Other colours are also available upon request

Post box: 205 Post code: 511

Muscat,

Sultanate of OMAN

Phone: +968 25691544

Email: Sales@aljazeerapanel.com

Shahidur.Rahman@aljazeerapanel.com

Website: www.AlJazeeraPanel.com